Would like to understand more?

Get In Touch Now!

What We do?

Technology

infrar3D has developed a novel laser preheating technology which makes FDM machines capable of producing components with more than double the tensile strength in comparison to conventional 3D-printers.

Why infrar3D

infrar3D specialties

Highest Safety Standards

Unique Technology Made by German Engineering

Suitable for industrial Environment with highest Requirements

Top Efficiency through Reinventing Ourselves every single day

What's new?

Innovation

3D printing processes work in layers

-> Adhesion of layers

-> Splices are weak points

Reduced intra-layer tensile strength towards inner-layer

-> Components tend to fail

Limited application of FDM process in industry

How can we increase inter-layer tensile strength on an industrial scale?

3D printing processes work in layers

-> Adhesion of layers

-> Splices are weak points

Reduced intra-layer tensile strength towards inner-layer

-> Components tend to fail

Limited application of FDM process in industry

How can we increase inter-layer tensile strength on an industrial scale?

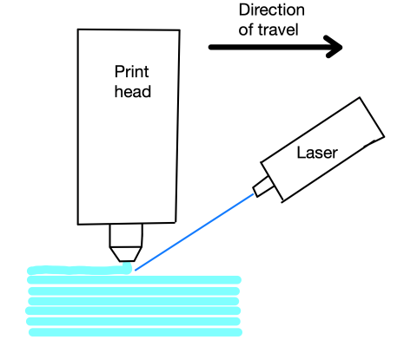

infrar3D’s Novel Laser Preheating Technology

What distinguishes infrar3D laser preheating from conventional FDM printers and other preheating developments?

Stronger Parts

- Additional thermal energy creates an extended time period for polymer chain diffusion across interface

- Increased bonding of layers

- Higher tensile strength in Z-direction (Build direction)

Independent of Direction

- During nozzle travel in any direction thermal laser energy is inserted into the part

- Every spot of component benefits from laser preheating

- Technology is first of its kind to be adequate for industrial use

Physically separated build chamber from laser and control unit

- Higher temperatures in build chamber are possible

- More variety of usable plastics such as ABS, PETG, PMMA, PC, etc.

- Reduced susceptibility to failure

- Increased maintenance possibilities, even during build process

- Adequate cooling of laser and control unit

- Change of filament during build process

- 24/7 use of machine

Safety First

- 100 % laser proof aluminum case with laser proof window and camera to observe in situ build process

- Safety circuit, when door is open, laser stops immediately

The team of infrar3D

The founding team of infrar3D has been working on the project since 2020 and is supported by the EXIST Founder Grant by German Government and European Union and the Jung Innovators program by Baden-Württemberg state ministry.

Dr.-Ing. Friedrich Bähr

CEO

- PhD : Quality Assurance in FDM

- Industrial Business Administration

- Entrepreneurship

Sarah Müller, Dipl.-Ing.

Material Development

- PhD : Quality Assurance in PBF

- Mechanical Engineering

- Materials Engineering

Georg Pröpper, B. Eng.

Technology Development

- Electronics Development Engineer

- Festool & Metabo

- Start-Up Experience

Prof. Thomas Bauernhansl

Advisor

- Head of Fraunhofer IPA

- Head of University of Stuttgart IFF

Sören Schölecke, B. A.

Tool Mechanic

- Industrial Design

Tobias Härdtlein, B. A.

Programmer

- Industrial Design

Zeba Ahmad

Intern

About Us

Our Vision

We aim to exploit full potential of the Material Extrusion process for high quality industrial production

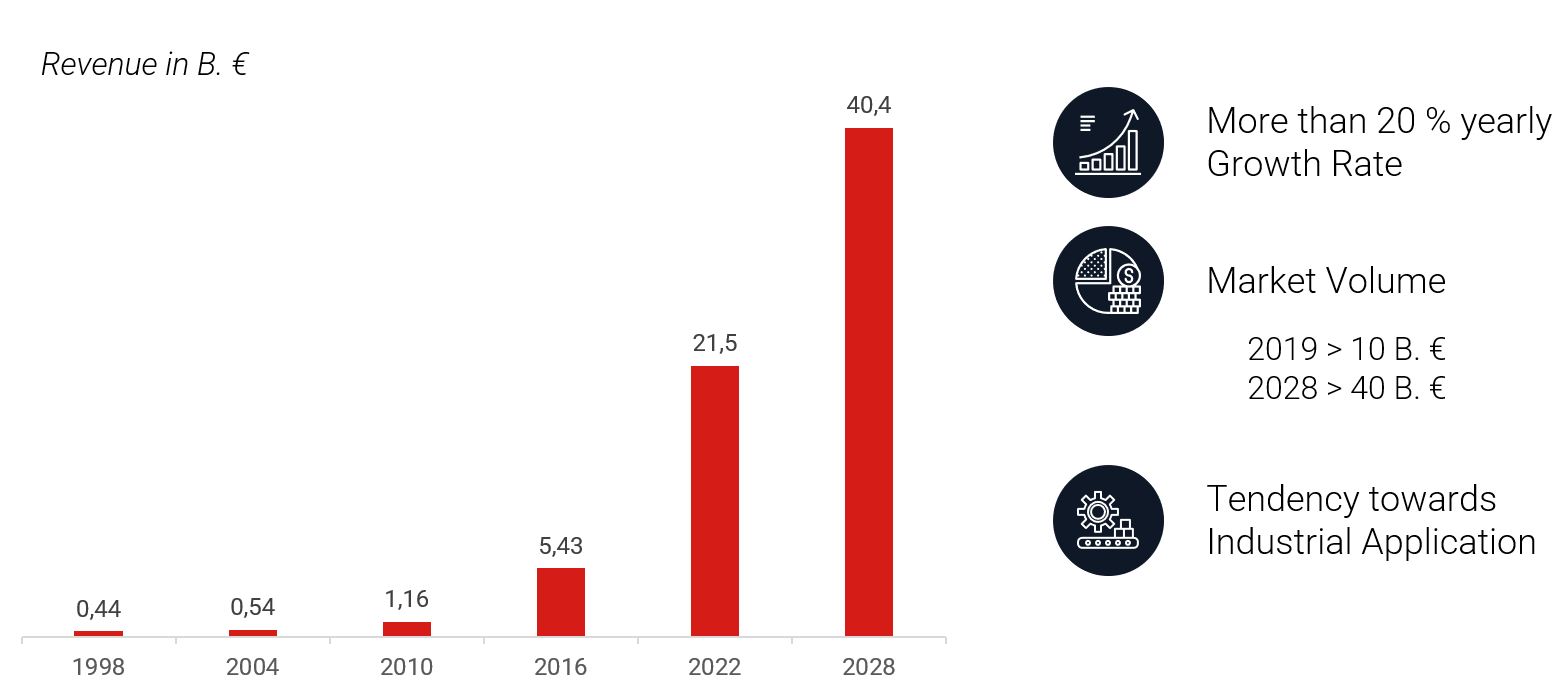

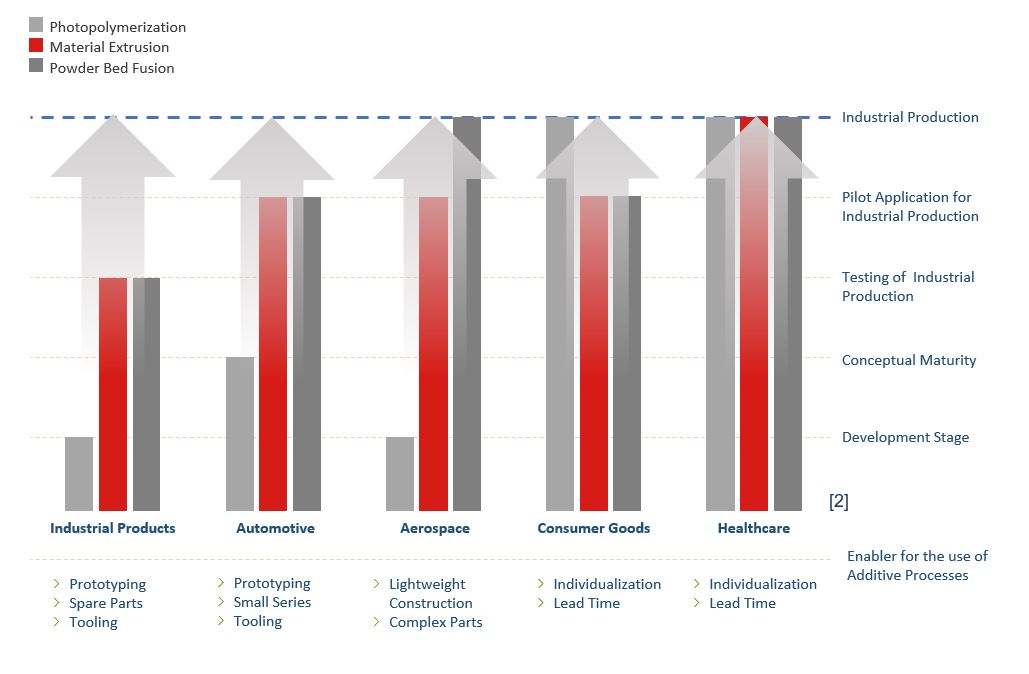

Additive Manufacturing Worldwide

- Additive Manufacturing Market is growing potentially

- Main growth in industrial applications

Source: MarketsAndMarkets, Oerlikon, Statista, Smithers Pira, SmarTech

Source: BMWi, TAB German Bundestag, Wohlers Associates, agiplan

Potential of additive Material Extrusion

- Potential of additive Material Extrusion processes is not fully exploited yet

- Increased part strength

- Weight reduction

- Faster production

- Conservation of resources

Use Cases

Case Study

Airbus A320

Substitution of aluminium armrests by plastic

- 240 pieces

- Weight reduction 37,3 kg

- Cerosine reduction / a 5,7 t

- Cost reduction / a 1.500 €

- Carbon Dioxide Reduction / a 17,9 t

- 60 % Weight Reduction

Sources: Stratasys, Inc., Prof. Witt, University Duisburg-Essen

Partnernetwork

Driving technology for leading brands

Special Thanks to our Sponsors